About DESH STEEL ERECTOR

All Kinds of Steel structure & Civil construction works Also Drawing, Design, Fabrication & Erection. We also making # Warehouse # Showroom # Shopping Centre # Supermarkets # Distribution Centre # Exhibition Hall # Factory Building # Aircraft Hangers # Cold Stores # Labour Camp # Park & Sports Centre # Office # Residential Building # Multy Story Building

Message from Chairman

A Desh Steel Erector is someone who rejects conventional behaviour.\r\n“Desh Steel Erectorl, we take pride in taking care of our customers.â€\r\nBelieve it or not, that sums us up pretty well. With a staff offering more than 10 years combined experience in the steel building industry, we knew what we liked and didn’t like about many of the common practices in this business. More importantly, we knew what our customers liked. That’s why we set out on our own in 2009 with the goal of bucking the trend of subpar business practices customers might find in dealing with other companies.\r\nWe founded Desh Steel Erector on a simple credo: to offer an excellent product paired with our signature “above-and-beyond†levels of service. We Construct for commercial, industrial, agricultural and residential use all across the nation. Equally important, Desh Steel Erector customers receive honest, straightforward, and friendly service that begins from the first phone call and doesn’t simply end the moment the contract has been signed.\r\nAt Desh Steel Erector, we don’t just Construct high-quality prefabricated steel buildings; we forge lasting relationships with the clients we serve. To us, customer service is not just fulfilling contractual obligations – it’s the willingness to go the extra mile. We believe it’s the right way to do business, and if that kind of unconventional thinking makes us as well take it!

Our Projects

Hazrat Shahjalal International Airport_Terminal-3

Dhaka, Bangladesh

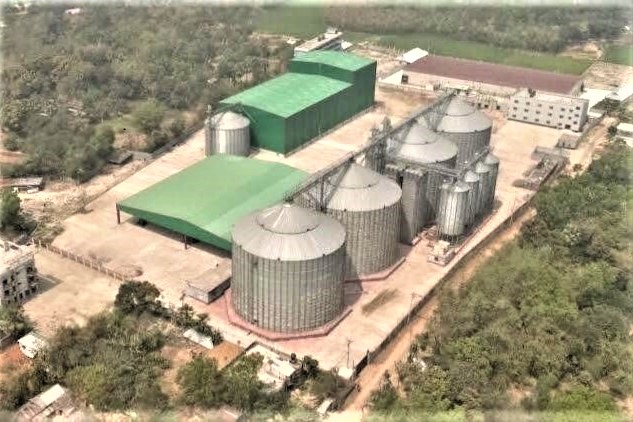

Diamond Feeds & Grains Ltd

Kapasia, Gazipur

Diamond Egg Ltd

Kapasia, Gazipur

Feed Mills, Diamond Feed & Grains Ltd

Kapasia, Gazipur.

Energy Pac (Transformer Factory)

Gazipur

FB Footwear-1

Baroipara, Gazipur

Sister Denim, Tharmax Group

Narsingdi

Sultana Filling Station, Tharmax Group

Narsingdi

Hasem Rich Mill

Rajshahi

A H Agro Firms

Chuadanga

Energy Fashion, Energypac Group

Hotapara, Gazipur

G Gas Store, Energypac Group

Bogura

4th Storied Garments Building, Desh Bondhu Group

Dakkhinkhan, Dhaka

Abrar Footover Bridge

Bashundhara Gate, Dhaka

Residential House

Gopalganj

5th Storied Office Building, Energy centre

Tejgaon, Dhaka

Watar Tank Tower-1, Diamond Egg Ltd

Kapasia, Gazipur

Connecting Mezzanine, Impress Newtex Composite Textiles Ltd

Gorai, Mirzapur, Tangail

Erection Project

zzzzzzzzzzzzzz

Kahdem Ceramics

Khadem Nagor, Sylhet

Continental Works Ltd

Nadda, Dhaka

FB Footware, Unit-1

Baroipara, Gazipur

Baly Yarn Dyeing

Hobirbari, Valuka, Mymensingh

Mezzanine Floor-1, FB Footwear-1,

Baroipara, Gazipur

2 Storied Office Building, Classical Handmade Products

Hazigonj, Niphamari

G gas Store, Energypac

Bogura

Ratul Garments, Jirabo,

Ashulia, Dhaka

4th Storied Garments Building, Desh Bondhu Group

Dakkhinkhan , Dhaka

Broiler Shed, Most Agro

Dhanghora, Gaibandha

Factory Building, SRCI

Turag, Dhaka

AkiJ Food & Beverage Ltd

Manikganj

Dream World Park

Hazaribagh, Dhaka

PDB Sub-Station

Ramgarh, Khagrachari

Duplex House, Dr. Golam Rabbani House

Gaibandha

Sultan Sir House

Masabo, Narayanganj

Uttara 12 No sector Mosque

Uttara, Dhaka

Alibaba House

Baroipara, Gazipur